About Us

Surging Power Originates from Jinna

Chongqing Jinna Power Technology Co., Ltd.

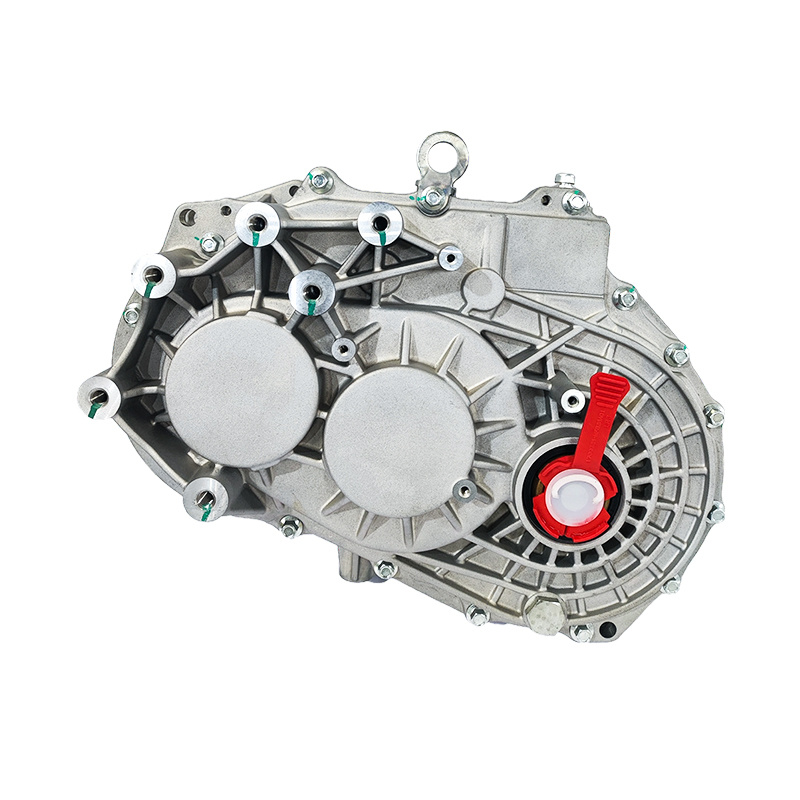

Chongqing Jinna Power Technology Co., Ltd. is a professional enterprise dedicated to the research, design, production, and sales of special new energy electric vehicle reduction gear assemblies, full series of ATV front and rear axle gearboxes/reduction gear assemblies, and differential assemblies. It has an annual production capacity of 600,000 sets of various gearbox assemblies and is a high-quality supporting supplier for dozens of vehicle manufacturers worldwide. It owns domestic first-class intelligent assembly lines for new energy vehicle and ATV gearbox assemblies, online comprehensive performance test benches, fatigue test benches, coordinate measuring machines, gear measuring centers, double-sided gear meshing measuring instruments, high-precision four-axis CNC machining centers, and various testing facilities.

Learn More

20 Years of Transmission Design, Production, and Testing Experience

43,000 Square Meters of Modern Intelligent Production Base

600,000 Sets Annual Transmission Production Capacity

210 Professional Staff to Meet Customer Needs

Product

Chongqing Jinna Power Technology Co., Ltd. is a professional enterprise dedicated to the R&D, design, production, and sales of special new energy electric vehicle transmission assemblies and a full range of ATV front and rear axle transmission assemblies.

Production Base

Equipped with domestic first-class intelligent assembly lines for new energy vehicles and ATVs (transmission assemblies), online comprehensive performance testing benches, fatigue testing machines, coordinate measuring machines, gear measuring centers, double-sided gear meshing measuring instruments, high-precision four-axis CNC machining centers, including metallographic, hardness, salt spray, tooling gauges, and other equipment and facilities.

Jinna Advantages

Our Core Advantages

20 Years of Accumulated Technical Experience

Comprehensive Product System

Top-tier Domestic R&D Team

Complete equipment and standardized processes for casting, machining, assembly, and testing stages.

24H Responsive After-sales Service

Cutting-edge Technology

Rich experience in design and application of front and rear axles and reducers for various domestic and international ATVs, special vehicles, and passenger cars, leading in various functional requirements ahead of users.

Excellent Equipment

Equipped with over 60 four-axis high-precision machining centers, more than 4 automatic assembly lines, over 2 fully automatic product cleaning lines, reducer comprehensive testing benches, gear testing centers, metallographic testing, coordinate measuring, and various other testing equipment.

Technical R&D Team

The company has a R&D team composed of professional technical personnel with intermediate and senior titles, providing strong technical support and assurance for product R&D, design, and manufacturing.

Quality Control

Jinna implements full-process control over product quality to ensure customers have no worries. We guarantee that all products within Jinna's supply scope are strictly reviewed and meet standards. Our quality department conducts rigorous supplier and product evaluations based on process standards (formulated according to the IATF16949:2016 quality management system).

Latest News

Equipped with domestic first-class intelligent assembly lines for new energy vehicles and ATVs (transmission assemblies), online comprehensive performance testing benches, fatigue testing machines, coordinate measuring machines, gear measuring centers, double-sided gear meshing measuring instruments, high-precision four-axis CNC machining centers, including metallographic, hardness, salt spray, tooling gauges, and other equipment and facilities.

Our professionalism is trustworthy; we welcome your valuable suggestions or opinions.

Customer First, Winning Trust with Quality; Continuous Improvement, Seeking Development through Innovation.

Leave a Message Now